As part of my current University project we have had to take an item that is designed in plastic steel or ceramics and re-design the object using a more sustainable material or a lower impact one. We have had to think about these materials and look into their strengths and weaknesses and the energy that is used to produce and manufacture these materials.

I have really struggled with this for a while as I couldn’t pin down what I wanted to look at which is why the blog has been so quiet recently. But I eventually settled on looking at a car dashboard unit being made from materials such as paper pulp and newspaper wood (which I have talked about it another post here). The reason I settled on these paper based materials is because I believe they hold real potential for our future. I know there are floors to these materials but there are flaws with all materials and I believe that by using fast growing trees in a well-managed area it could lead to a successful manufacturing chain but not a perfect one.

I remember I was watching Top Gear UK recently and they were talking about the Peugeot Onyx concept car that used newspaper wood for the dash-board and this to me was a brilliant idea and I wanted to see if I could take it further and progress it as Peugeot were just using it for the skin of the dashboard. But my thinking is to use it for the substructure as well.

My thought process about the material actually started when I was on a train journey. I kept seeing people with newspapers who would just leave them on the train when they left. This lead me to wondering about what happens to all the newspapers that aren’t sold each day ,what happens to them? After asking some local shops I found out that they were collected at the end of the day and taken back to the newspaper manufacturer for recycling and reusing.

After a lot more research into the newspaper production chain I thought well if I can just add a detour into the life cycle of a newspaper I could reduce the amount of plastic used in a car. I will explain what I mean.

If when a newspaper isn’t sold or when a person throws it away into recycling instead of going to a recycling plant or a paper factory, if instead it went to a car manufacturer or a local company that made the dashboards for a car company then the paper could be transformed into a dashboard unit. Then after the car has lived its life the dash unit could be ripped out and recycled using the normal methods and put back into the paper cycle. Maybe its then used again for another newspaper. This could in theory mean that the newspaper you read one day is in the new car you buy the next day.

I know this is all just theoretical and there are big holes in the idea but I believe it could work for companies that turn out lower numbers of cars each year such as Morgan or Caterham or even slightly bigger companies like Ferrari or Lamborghini.

I have since been experimenting with paper pulp and newspaper wood to see what is possible and what level of finish can be achieved. I have been impressed by the strength of the material and the simple method used to create it.

I hope you have enjoyed reading this, Let me know what you think or any advice you might have.

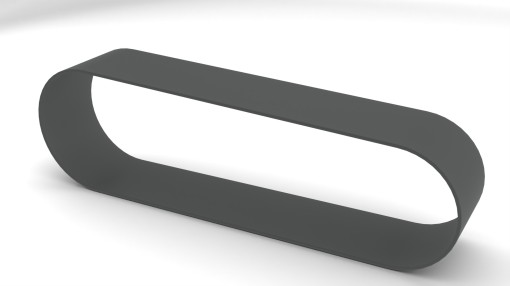

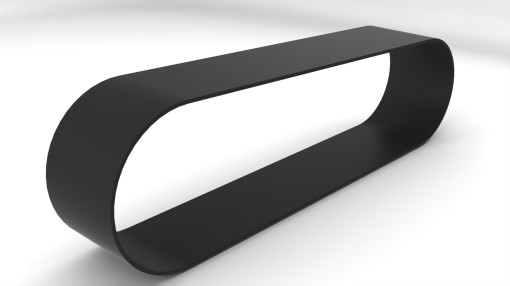

Student Render.